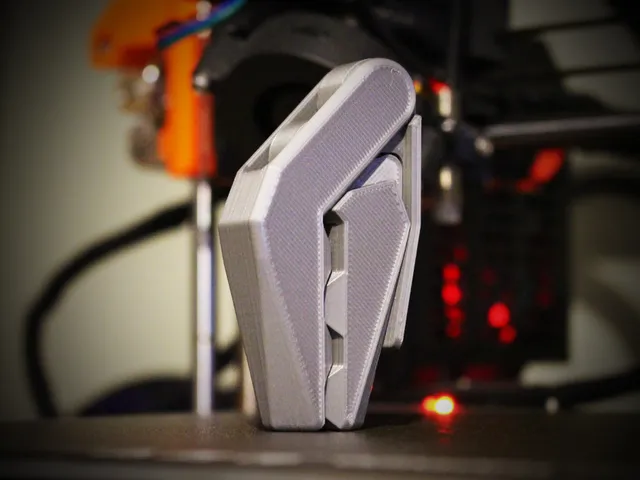

An elegant bag clip designed to be printed in place as one piece with minimal supports. Once printed, the clip is freed into 3 hinged components. The design uses a specially designed cam to give the user a mechanical advantage and lock in place.

The clip opens to approximately 30deg and closes such that there is a clearance of 1mm between teeth. The tolerances were designed to provide smooth motion without any play when printed with PLA on an MK3S.

Starting from an open position, the curve on the first quarter turn of the cam is designed to quickly bring the clip to an almost close. The next quarter turn has a polar slope of 10deg (this was measured to be less than the slip angle for PLA). This section provides the maximum mechanical advantage and is non-backdrivable. The last small portion of the cam has a constant radius to provide a satisfying lock.

Check out 3D Printing Nerd’s video about this clip:

Print instructions

The 3 components of the clip should be printed all at once in the same position as in the STL/3MF.

Supports should be set to “Support on build plate only”.

15% infill works great. However, you can increase the infill for greater strength.

0.15mm layer height should be used. This is because the vertical clearances are 3*0.15mm. Other layer heights will affect the resulting clearances after slicing and could make the parts harder to break free.

The regular files have a 0.1mm clearance on the shaft. For printers requiring a greater clearance, the 015Tol, 02Tol, and 03Tol files have a 0.15mm, 0.20mm, and 0.30mm clearance respectively.

NOTE: It is recommended that you use the 3MF file as it contains some useful support blockers and all the correct settings.

Credits:

Andrei